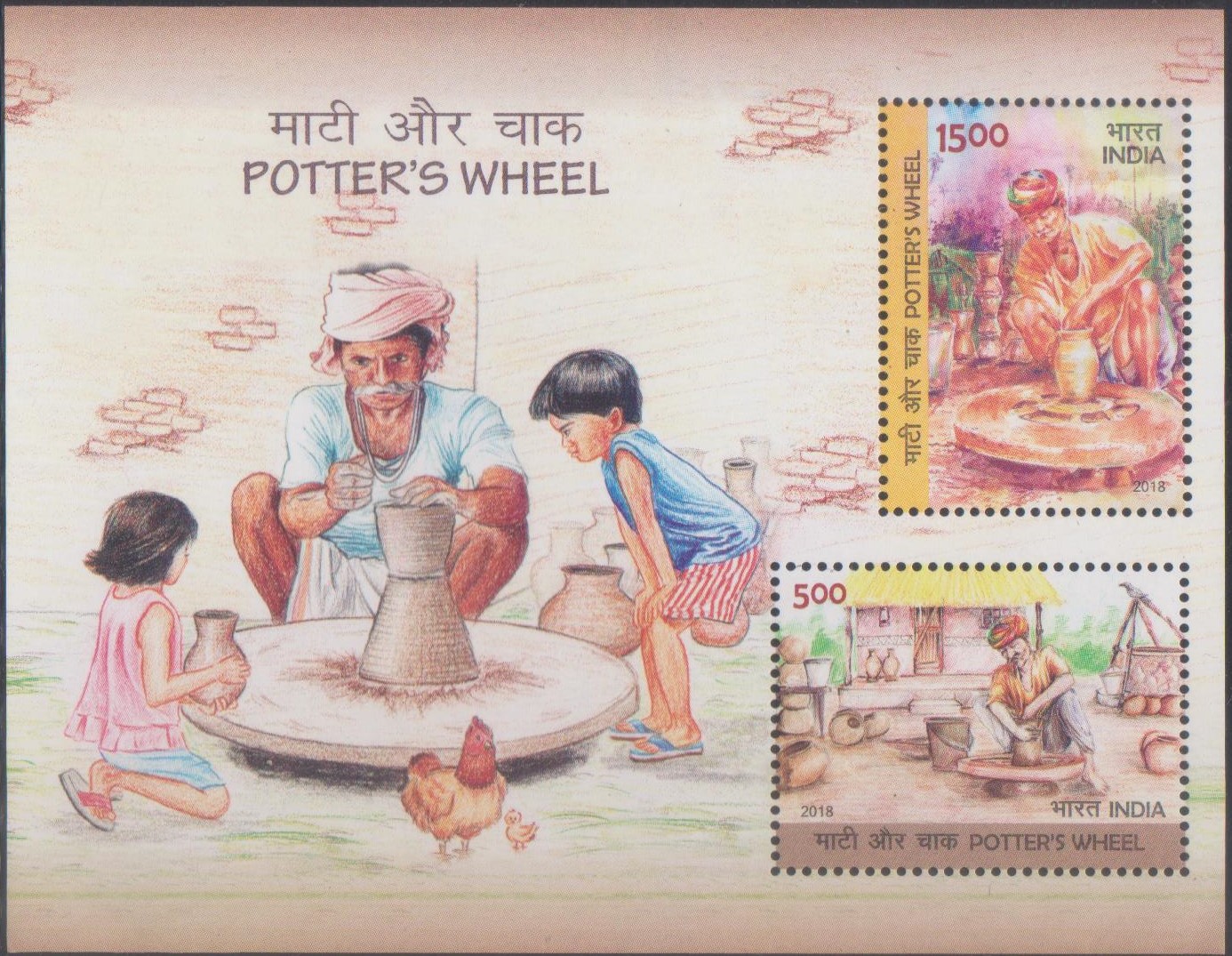

Potter’s Wheel

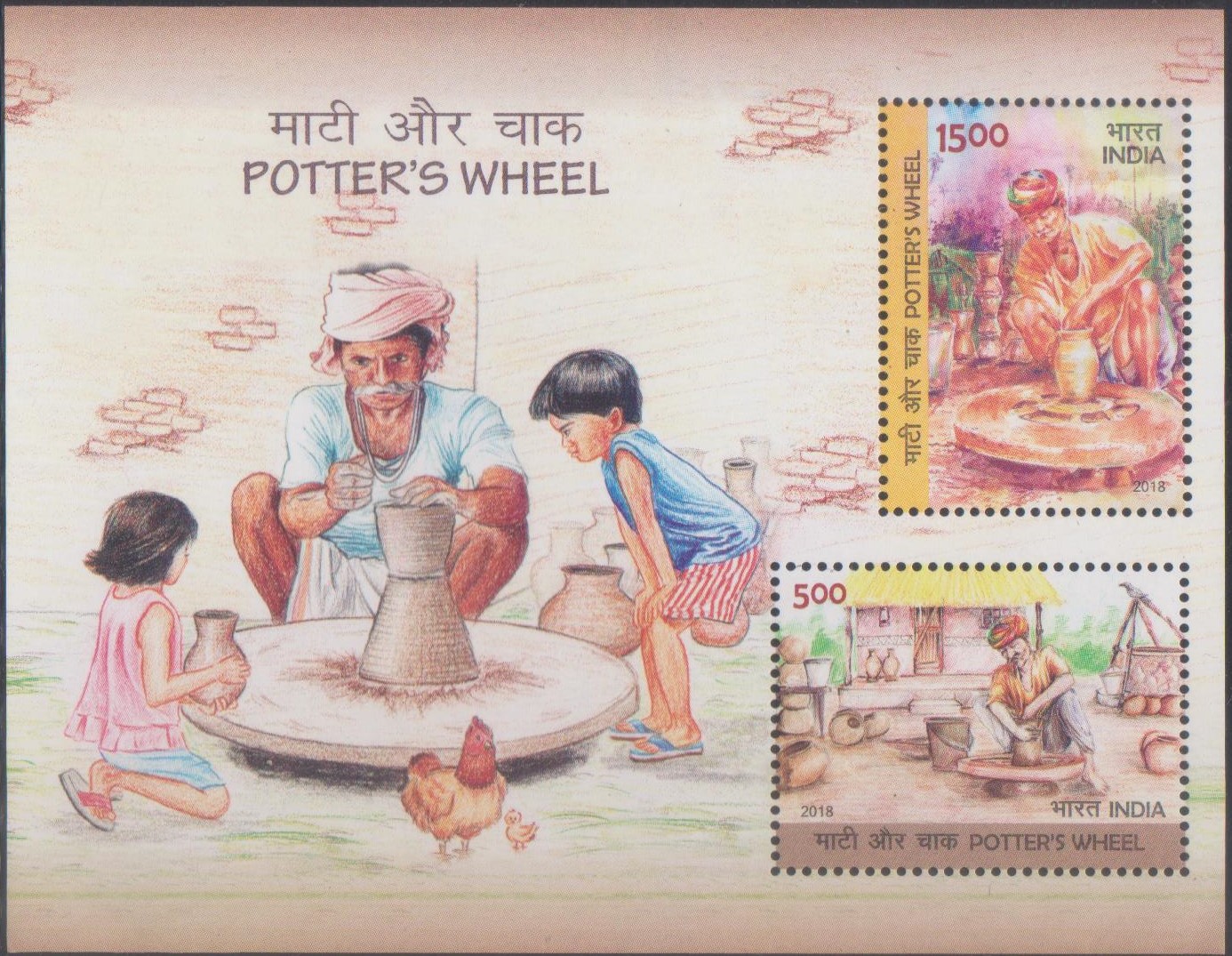

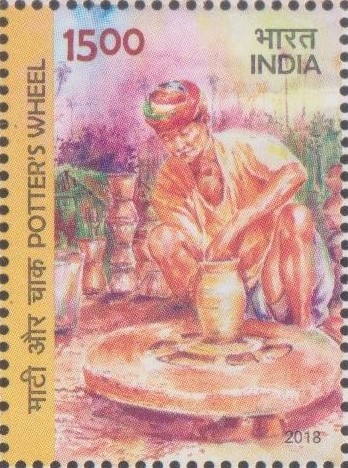

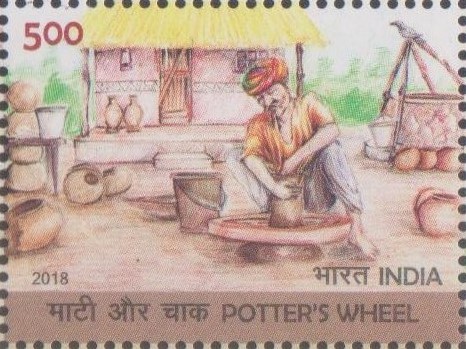

Complete set of 2 nos. of special postage stamps on the Potter’s Wheel, a machine used in Pottery :

Issued by India

Issued by India

Issued on Jan 26, 2018

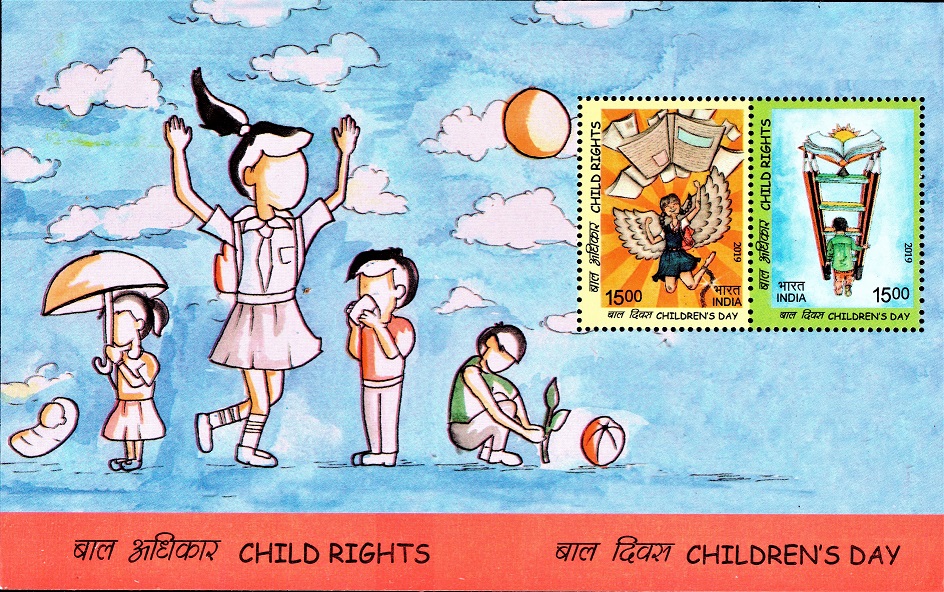

Issued for : Department of Posts is pleased to issue a set of two Commemorative Postage Stamps, a miniature sheet, an FDC, a brochure and five maxim cards on Potter’s Wheel on the selected entries.

Design : On the theme “Potter’s Wheel”, entries from each corner of the country were received. All the entries were carefully examined and thereafter eight entries received from Mr. Abin Bhanu, Mr. Gokul Raghavan, Ms. Sonal Kewalramani, Mr. Vysakh. K. S., Mr. M. Vaibhav Shenoy, Mr. Sanskar Verma, Mr. Abhishek P and Mr. Sumit Namdev Mandre have been selected as prize winning entries. Based on the selected entries, two stamps, a miniature sheet, a first day cover and a brochure have been designed. Five entries received from Ms. Bharati Manjari Naik, Mr. Jayasooryan S, Ms. Kumud Krishnakumar Kedia, Mr. Bandana Kumar and Ms. Malavika Sunil have also been selected and on their designs five maxim cards are also being released.

Credits :

Stamp/Miniature Sheet/Maxim Cards/FDC/Brochure/Cancellation Cachet : Smt. Nenu Gupta, based on the selected entries.

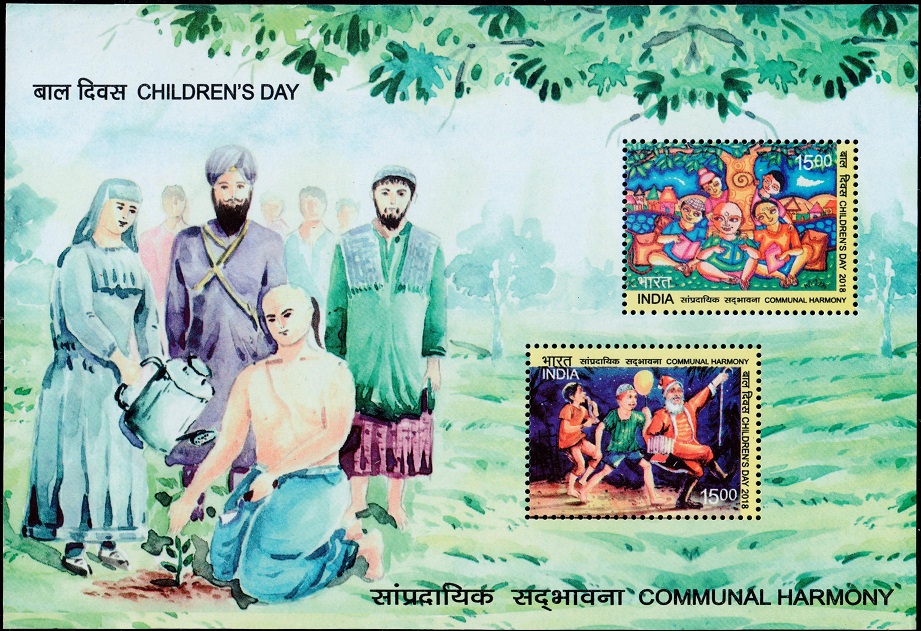

Type : Miniature Sheet, Mint Condition

Colour : Multi Colour

Denomination : 1500 & 500 Paise

Stamps Printed : 5.0 lakh each

Miniature Sheet Printed : 1.10 lakh each

Maxim Cards Printed : 1000 each

Printing Process : Wet Offset

Printer : Security Printing Press, Hyderabad

About :

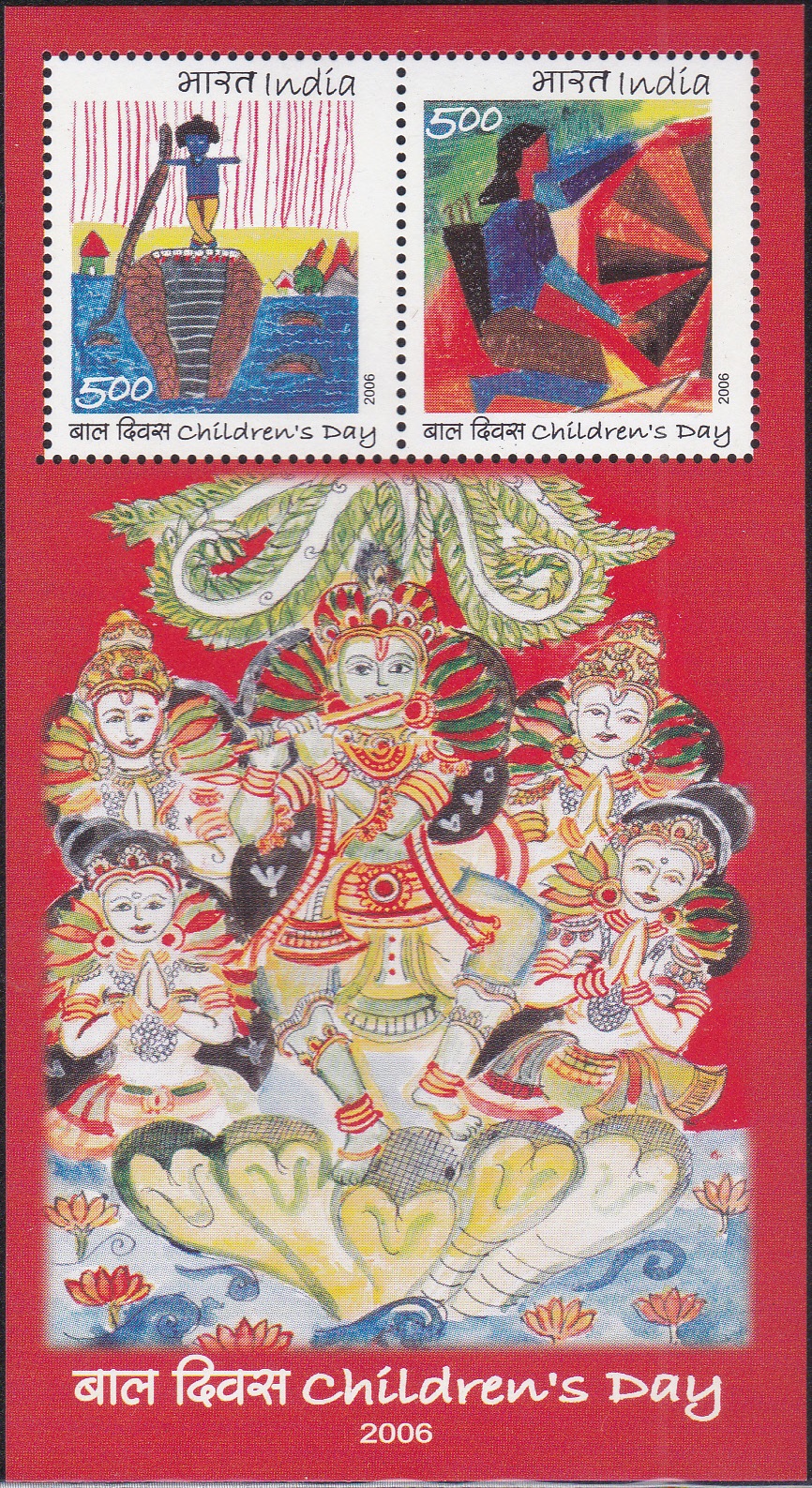

- Every year on the occasion of Republic Day, Independence Day and Children’s Day, Department of Posts has been conducting stamp design competition at All India Level since 2015. The selected entries are awarded with the cash prizes and these entries are used in design of stamp and other philatelic items. This time Department has conducted a stamp design competition on the theme of “Potter’s Wheel”. With support of 23 Circle offices across the country, Department has got wide response for this competition.

- Pottery, the art of making pots out of burnt clay, is an ancient art. Pieces of pottery are inevitable parts of archaeological digs all over the world. The oldest evidence of pottery dates back to 10,000 BC in Japan. The concept of clay made vessel sprung up when the society shifted from nomadic to agrarian. The society was in need for stable but heavier containers leading to the art of pottery.

- Much early ceramic ware was hand-built using a simple coiling technique in which clay was rolled into long threads that were then pinched and beaten together to form the body of a vessel. In the coiling method of construction, all the energy required to form the main part of a piece is supplied indirectly by the hands of the potter. Early ceramics built by coiling were often placed on mats or large leaves to allow them to be worked more conveniently. The evidence of this lies in mat or leaf impressions left in the clay of the base of the pot. This arrangement allowed the potter to rotate the vessel during construction, rather than walk around it to add coils of clay. The earliest forms of the potter’s wheel (called tourneys or slow wheels) were probably developed as an extension to this procedure. Tournettes, in use around 4500 BC in the Near East, were turned slowly by hand or by foot while cooling a pot. Only a small range of vessels were fashioned on the tournette, suggesting that it was used by a limited number of potters. The introduction of the slow wheel increased the efficiency of hand-powered pottery production.

- In the mid to late 3rd millennium BC the fast wheel was developed, which operated on the flywheel principle. It utilised energy stored in the rotating mass of the heavy stone wheel itself to speed the process. This wheel was wound up and charged with energy by kicking, or pushing it around with a stick, providing a centrifugal force. The fast wheel enabled a new process of pottery-making to develop, called throwing, in which a lump of clay was placed centrally on the wheel and then squeezed, lifted and shaped as the wheel turned. The process tends to leave rings on the inside of the pot and can be used to create thinner-walled pieces and a wider variety of shapes, including stemmed vessels, so wheel-thrown pottery can be distinguished from handmade. Potters could now produce many more pots per hour, a first step towards industrialization.

- Text : Philately Division, Department of Posts.